Challenge

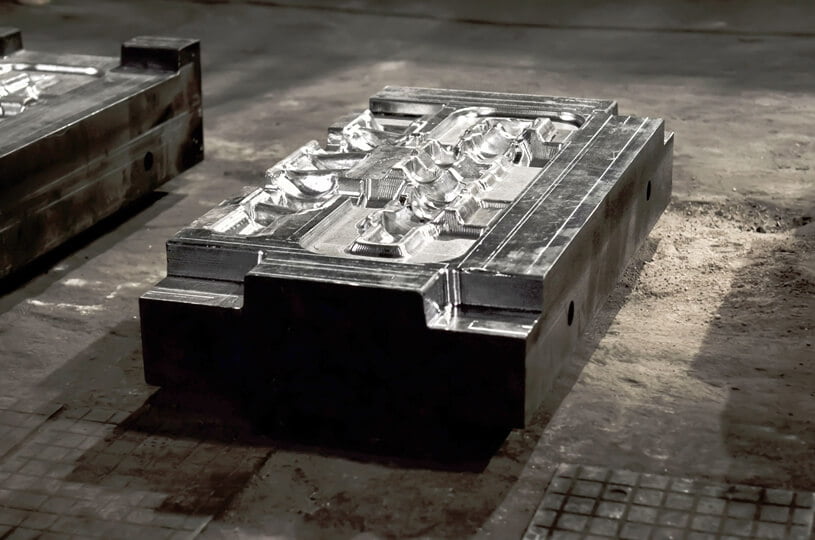

A steel forging company supplying the automotive industry had an increasing number of products with underfill defects. This resulted in longer production cycle times and higher production costs from reworking of the underfilled forged parts.

Our Solution

Resource One’s team of lubrication experts assessed their process and recommended the use of Condat Condaforge 317 forging lubricant which exhibits better graphite particle suspension and dispersion compared to the previous lubricant used. At high temperatures, a graphited film with exceptional adhesion is formed preventing the occurrence of the underfill defect.

Impact

The company was able to reduce the underfill defect rate from 0.63% to only 0.22%. This minimized the need for reworking, providing savings of up to Php 1,500.00 per day.

Product Information

Condat Condaforge 317 is a high-performance water-based forging lubricant for hot forging of steel, aeronautics’ alloys (Inconel, titanium, etc.) and aluminum. Its advantages include:

- Ammonia-free

- Does not cause deposits on tools

- Easy to mix and dilute

Industry Expertise

Resource One’s extensive experience in forging lubrication and other industries in metalworking spans more than two decades – ensuring that lubrication issues are thoroughly investigated and properly addressed. Speak with our lubrication experts for consultation on your machine lubrication and maintenance.