Challenge

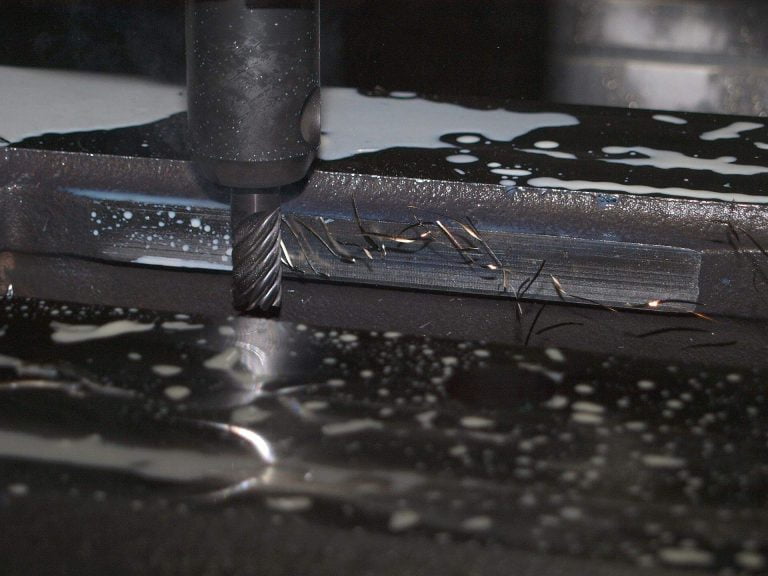

An engineering company producing gear reducers for robotics and industrial automation experienced excessive coolant foaming during operation resulting to the following problems:

- Wet and slippery factory floors from overflowing sump tanks which adds risk of injury to workers

- High coolant consumption from frequent top-up and replenishment

Our Solution

Resource One’s team of lubrication experts recommended the use of Quakercool 820 CF coolant – a water dilutable machining and grinding fluid developed using advanced synthetic ester technology which provides little to no foaming in most water hardness conditions. The chemistry of the product also contributes to its good lubricity, excellent emulsion stability, and advanced biostability characteristics.

Impact

The shift to a more stable coolant eliminated the excessive foaming issue, benefiting the company with:

- Improved workplace safety since factory floors are no longer wet and slippery from overflowed coolant

- Decreased coolant consumption by 15% usually from top-up and replenishment of wasted coolant

Product Information

Quaker Quakercool 820 CF is a biostatic machining and grinding fluid suitable for auto engine parts manufacturing applications and all machining operations on non-ferrous and ferrous applications.

Industry Expertise

Resource One’s extensive experience in machining and grinding lubrication and other industries in metalworking spans more than two decades – ensuring that lubrication issues are thoroughly investigated and properly addressed. Speak with our lubrication experts for consultation on your machine lubrication and maintenance