Challenge

A manufacturer of high precision machined parts for various industries encountered oil separation when using industrial water to dilute their cutting coolants. This resulted in frequent coolant replacement (only 4 weeks sump life) for their 80 CNC machines, forcing them to shift to the more costly treated water. While the oil separation issue was addressed, several problems arose upon using treated water such as:

- Additional production expense and lengthy procurement procedure for treated water (approx. 30,000 L consumed over 8 weeks)

- Decreased productivity with added workload for the workers in transferring and handling the treated water instead of focusing on production

Our Solution

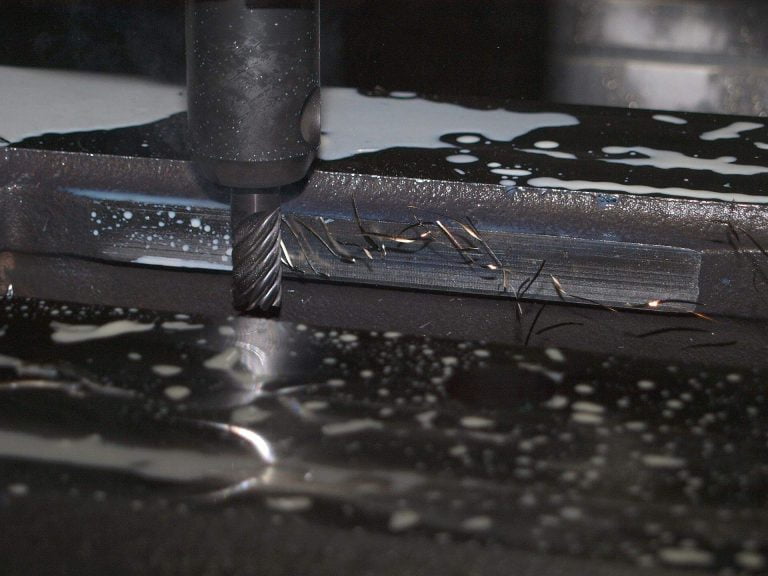

Upon a thorough survey of their process and application, lubrication experts from Resource One recommended the use of Quakercool 7200 HBFF coolant. The product exhibits excellent biostability and emulsion stability allowing use with BOTH soft and hard water.

Impact

The company was able to revert to industrial water to dilute the coolant without any oil separation problems. This translated to:

- Savings from production expense and troublesome procedure of procuring treated water

- Increased productivity since workers no longer need to transfer and handle treated water

- Increased sump life from 4 weeks to 12 weeks resulting to decreased coolant disposal costs (approx. 30% less)

Product Information

Quaker Quakercool 7200 HBFF is a Boron-free metalworking water soluble coolant ideally suited for all operations where high surface finish quality and high lubrication is needed. Use for general purpose machining operations on steel, cast iron and aluminum alloys. Product benefits include:

- Excellent wetting and onctuosity abilities giving high cutting performances

- Formaldehyde-free

- Boron-free

- Mild smell

Industry Expertise

Resource One’s extensive experience in machining and grinding lubrication and other industries in metalworking spans more than two decades – ensuring that lubrication issues are thoroughly investigated and properly addressed.