Chemical companies commonly manufacture release agents or die lubes as emulsion, a mixture of water, oils, and chemicals/solids (10-30% of its total components). Before using the high pressure die casting machine (HPDCM), emulsions are diluted with water with ratios ranging from 1:20 to 1:250. Below are some of the main functions of die cast release agents:

Cooling to Protect the Die

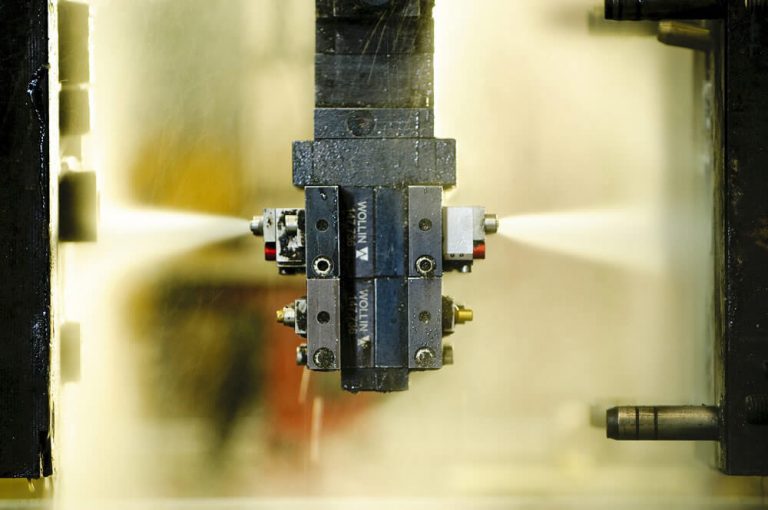

This step is essential in times of mass production and helps lessen production costs. Cooling happens through the use of water-based die lube when sprayed into the die cavity. It will highly absorb the heat of the die surface, preventing it from premature failure or wearing of the die due to extreme temperature.

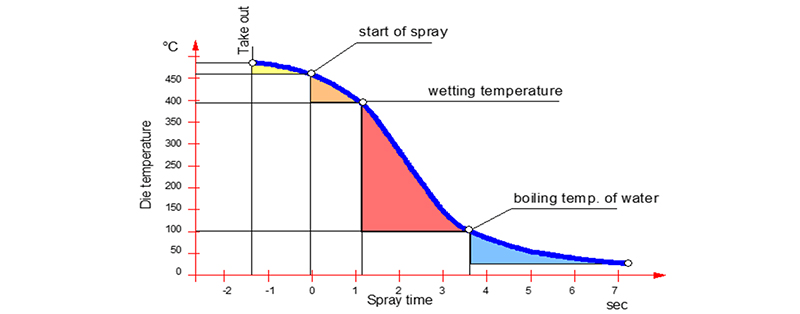

Hence, applying the proper amount to its surface to attain its lowest temperature should be done, in which die temperatures as high as 500 °C may lower to >200 °C. Although, other mechanisms play a significant role in lowering the temperature, such as the cooling system of the die and convection.

Formation of lubricating and barrier film

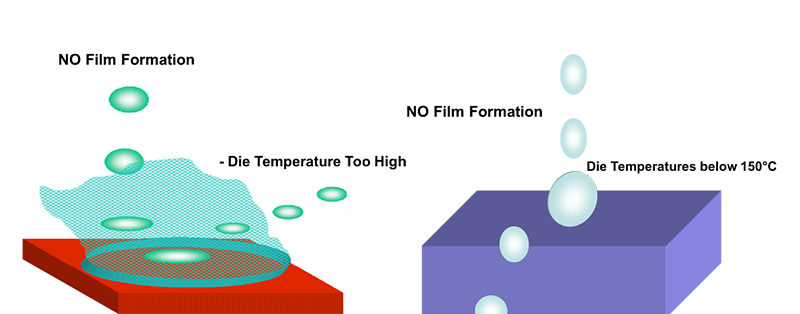

Liedenfrost Effect is a phenomenon that happens when die lube particles (also the solids) hit the hot die and mostly bounce off on the surface due to the temperatures higher than 400 ̊C. While at lower temperatures, a significant amount of applied die-lube might leak down from the die.

With this in consideration, the next phase is when the die is cooled down to reach the “wetting temperature,” which ranges from below 400°C up to 150°C. This is the optimal temperature range where the water component is vaporized and the solids in the die lube adhere to the surface of the die cavity. This forms a thin, uniform lubricating and barrier film between the die and injected molten metal.

Prevent Soldering

With the formation of the barrier, sticking of certain portions of the casting to the die, also known as soldering, is prevented.

Even with the optimum temperature range, there are other aspects that the professional die caster must control to produce a “good, uniform” cast that is free from soldering, acceptable and economical, such as the following:

- Varying die cavity geometry depending on produced parts

- Inconsistent surface temperatures of die’s certain areas

- Die lube spray volume, spray time, and spray position consistency

- Quality of chemistry and dilution ratios of die lube

- Properties of metal alloys to be casted

In addition to release function, barrier formation of solids should be considered because it affects the casting’s appearance and structural integrity, allowing the production of desirable bright, shining, stain-free casting.