In machining and grinding operations, the machine operator’s responsibility does not end after adding the coolant to the sump, but continues up to the monitoring and maintenance of coolant concentration. When the correct concentration is used, coolant performance is optimized in terms of:

- Fluid stability (no oil-phase separation)

- Rust and Corrosion control

- Lubricity for prolonged tool life and good surface finish

- Resist bacterial growth

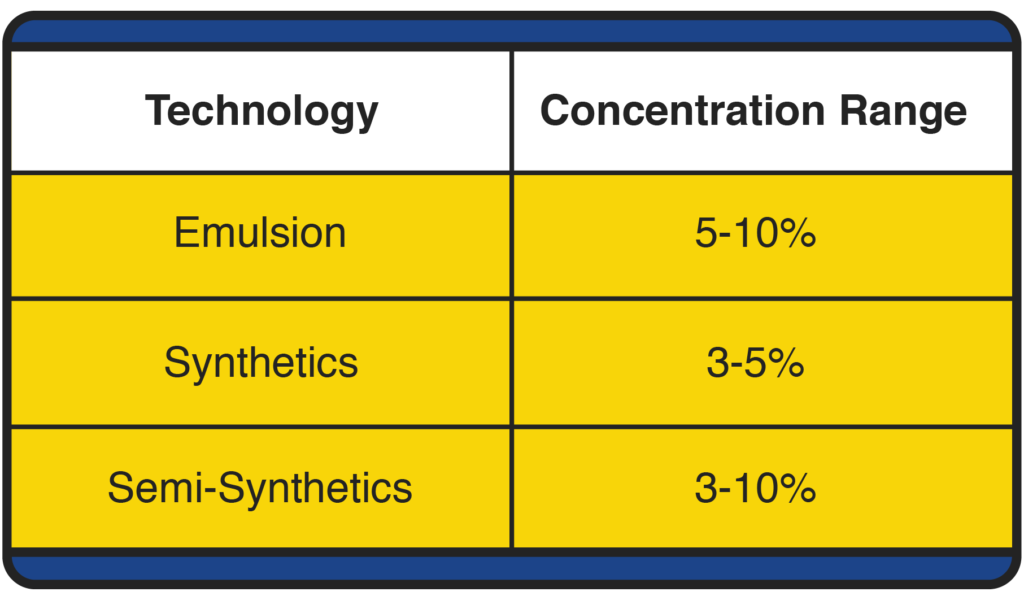

The concentrations required depend on the machining or grinding process, but the guidelines below apply.

Maintaining and monitoring concentration might seem easy, yet operators lack the tools for accurate measurement. As a solution, the metalworking industry widely adapted and performs concentration checks through a refractometer, an optical instrument initially designed to measure sugar concentration in solutions. The machine operator can determine whether to fill up with a “stronger” or a “weaker” mix based on the obtained result from a glance through the eyepiece or digital screen depending on the type of refractometer used.